OUR PRODUCTS

-

Details

A PDM (Power Distribution Module) is a device used to replace conventional relays and fuses in a vehicle electrical system. The Hardwire Electronics PDM takes inputs from physical switches, analogue voltages, or the CAN bus, and provides power to different electronic devices such as radiator fans, fuel pumps and head lights. The current being drawn from each connected device is continuously monitored. If the measured current is too high due to a fault, the PDM switches off the respective output to prevent further damage to the wiring loom or the connected device. The PDM can then retry the output to see if the fault has cleared.

-

Details

A PDM (Power Distribution Module) is a device used to replace conventional relays and fuses in a vehicle electrical system. The Hardwire Electronics PDM takes inputs from physical switches or analogue voltages, and provides power to different electronic devices such as radiator fans, fuel pumps and head lights. The current being drawn from each connected device is continuously monitored. If the measured current is too high due to a fault, the PDM switches off the respective output to prevent further damage to the wiring loom or the connected device. The PDM can then retry the output to see if the fault has cleared.

-

Details

A PDM (Power Distribution Module) is a device used to replace conventional relays and fuses in a vehicle electrical system. The Hardwire Electronics PDM takes inputs from physical switches, analogue voltages, or the CAN bus, and provides power to different electronic devices such as radiator fans, fuel pumps and head lights. The current being drawn from each connected device is continuously monitored. If the measured current is too high due to a fault, the PDM switches off the respective output to prevent further damage to the wiring loom or the connected device. The PDM can then retry the output to see if the fault has cleared.

-

Details

A PDM (Power Distribution Module) is a device used to replace conventional relays and fuses in a vehicle electrical system. The Hardwire Electronics PDM takes inputs from physical switches, analogue voltages, or the CAN bus, and provides power to different electronic devices such as radiator fans, fuel pumps and head lights. The current being drawn from each connected device is continuously monitored. If the measured current is too high due to a fault, the PDM switches off the respective output to prevent further damage to the wiring loom or the connected device. The PDM can then retry the output to see if the fault has cleared.

-

Details

Introducing the TTR CNC USA 2JZ Dry Sump, a pinnacle of precision engineering designed exclusively for high-performance cars, and specifically tailored for the legendary 2JZ engine. Elevate your engine’s capabilities with this cutting-edge dry sump system, meticulously crafted to enhance oil control and overall performance in demanding driving conditions.

Key Features:

- Precision Machining: Crafted with unparalleled precision using state-of-the-art CNC technology, our 2JZ Dry Sump ensures exacting tolerances for optimal fit and function.

- Enhanced Oil Control: Experience superior oil management with the multi-stage pump, providing consistent and reliable lubrication even under extreme G-forces and high-speed maneuvers.

- High-Grade Materials: Built to withstand the rigors of high-performance driving, the 2JZ Dry Sump is constructed from top-quality materials, ensuring durability and longevity.

-

Details

A billet replacement for the OEM cast part, reinforced for high power outputs, machined from aerospace-grade aluminum with revised port geometry, it represents the pinnacle of head design while maintaining the OEM port pattern. Enhanced combustion chamber geometry improves tumble and burn rate, surpassing the performance of the original cast head.

-

Details

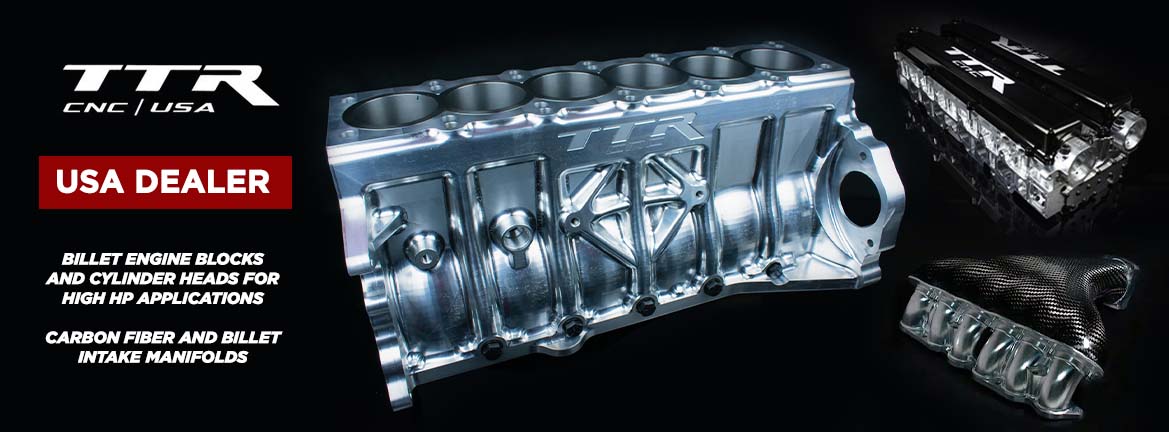

Designed to suit the original hardware with all the necessary reinforcements to suit a high performance use.

Machined in aeroespace grade aluminum 6061 T6 using up to 5 axis machines and fitted with ductile iron sleeves. All the TTR CNC blocks are optimized using finite elements method simulations exploring different RPM ranges, rotating assemblies weights and maximum torque/power boundary conditions to ensure a product that can withstand all the stress that it is going to be imposed.

With a aluminum 7075 T6 machined girdle giving the block extra stability, we tried to achieve the best features for a streetable block.

-

Details

Crafted to precisely complement the original hardware, incorporating essential reinforcements for optimal high-performance use. Precision-machined from aerospace-grade aluminum 6061 T6 utilizing advanced 5-axis machines and enhanced with ductile iron sleeves. Each TTR CNC block undergoes meticulous optimization through finite element method simulations, evaluating various RPM ranges, rotating assembly weights, and maximum torque/power conditions, ensuring resilience against all anticipated stress factors.

Equipped with Chrome-Moly main caps, the block is engineered to withstand rigorous usage and abuse, guaranteeing lasting durability and performance.

OUR PARTNERS

INSTAGRAM: @drtracing